Skills

Formulation

and implementation of materials

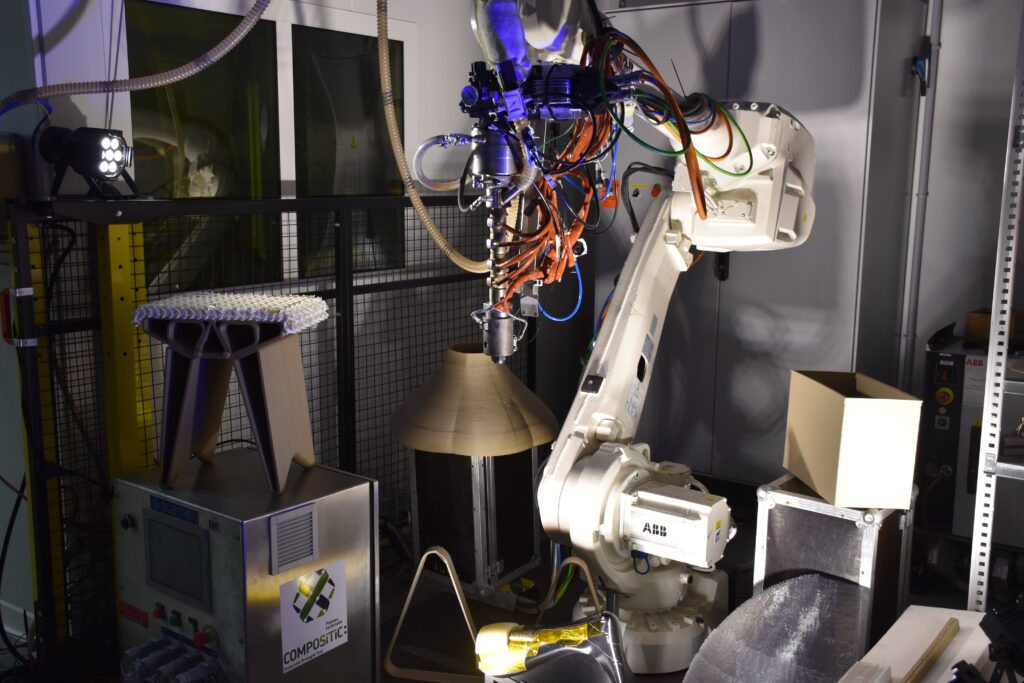

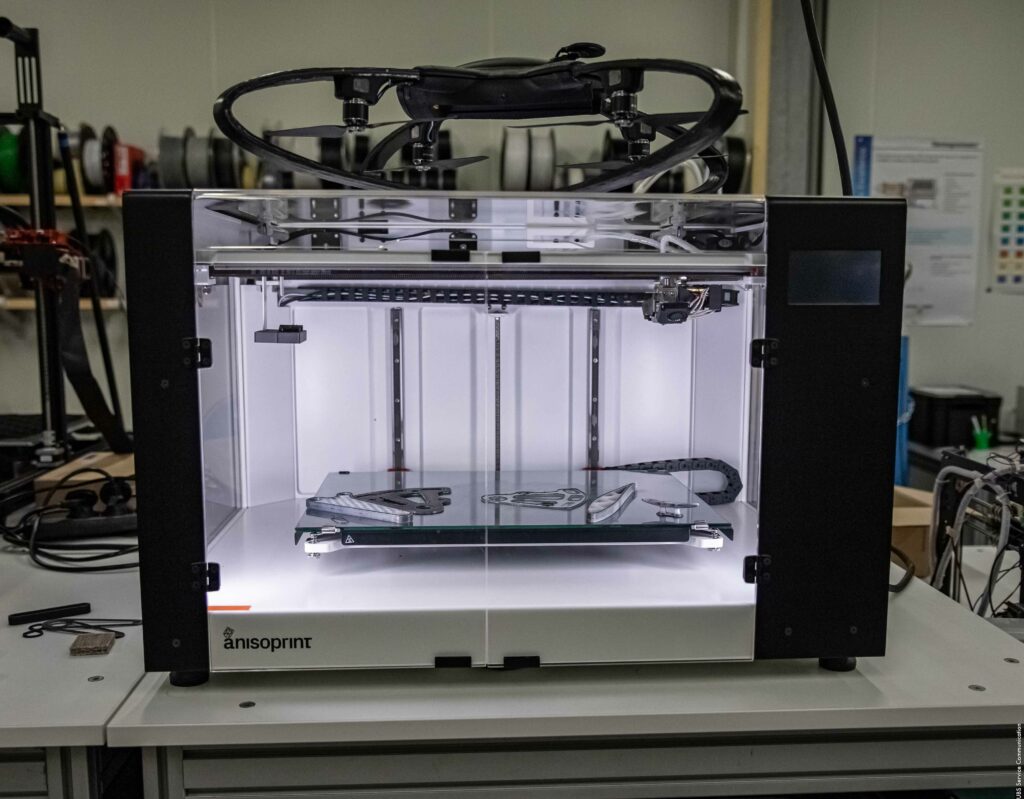

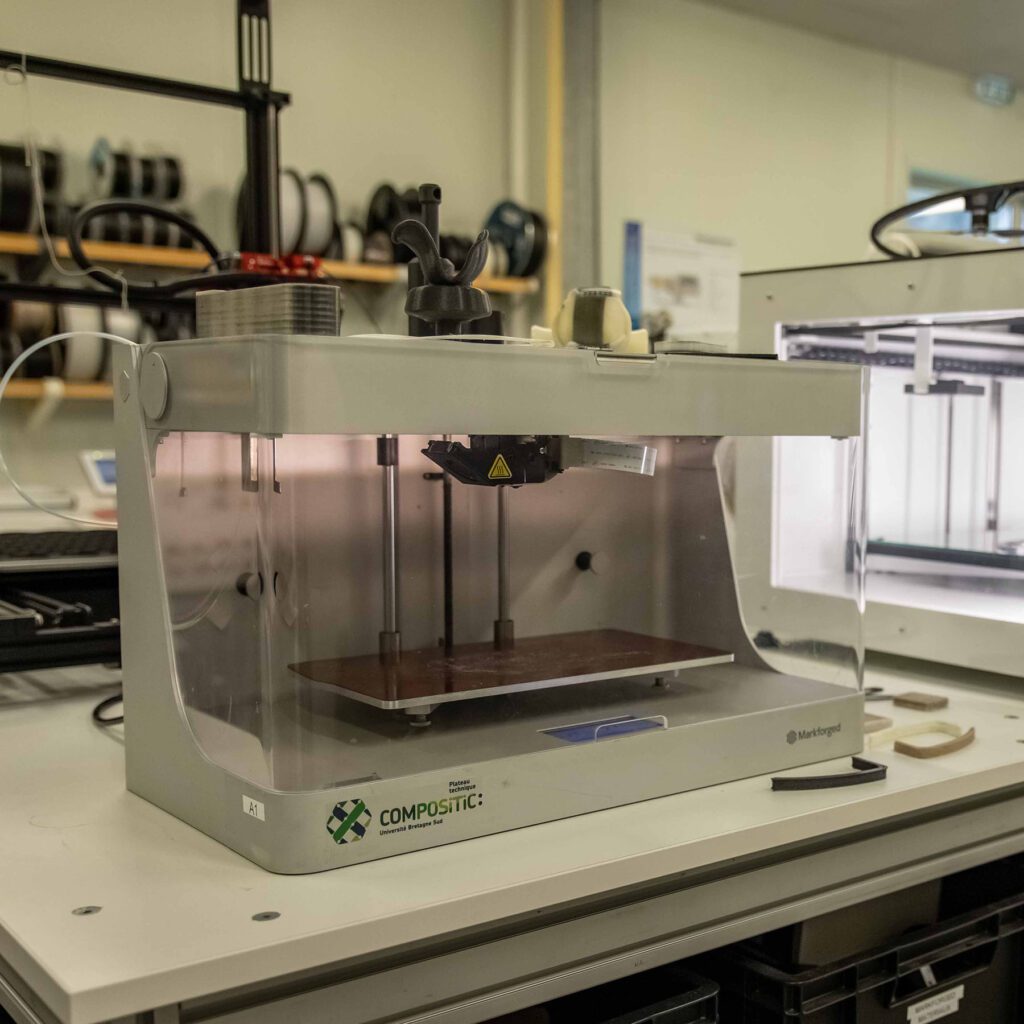

ComposiTIC specialises in the formulation of polymers and composites including the means of implementation in different configurations (filament, tube, sheathing, film, fibre impregnation).

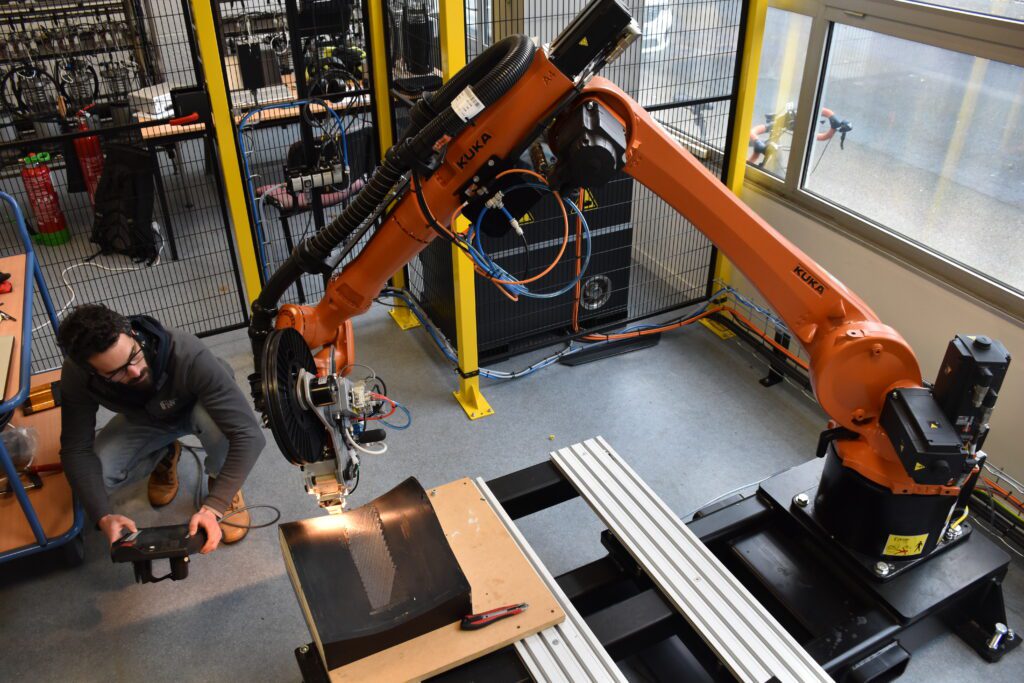

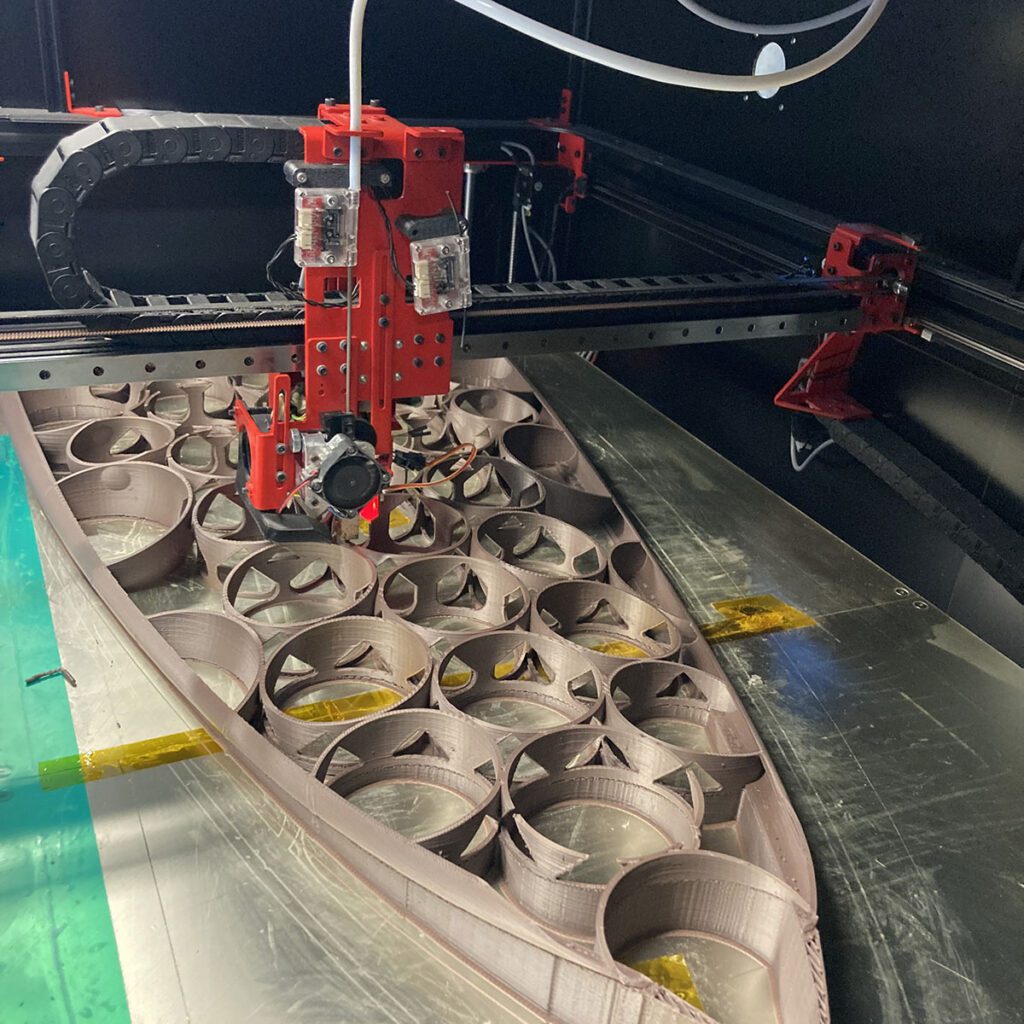

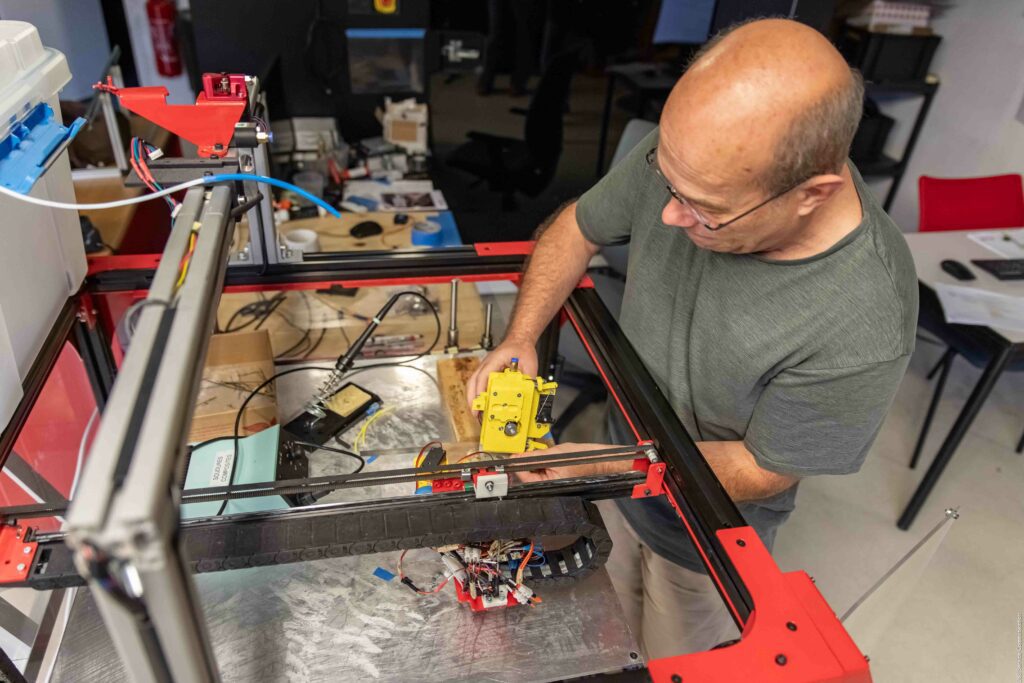

Additive processes

Characterisation

In addition to these means of implementation, ComposiTIC has thermal (DSC, DMA), mechanical and rheological characterisation resources to exhaustively characterise the properties of the formulations developed.

The characterisation of the end-of-life of materials also falls within the structure’s remit, with ageing tests in controlled or natural conditions and assessment of their biodegradability (industrial, domestic or natural composting).

HYDROGEN FOCUS

HYDROGEN FOCUS

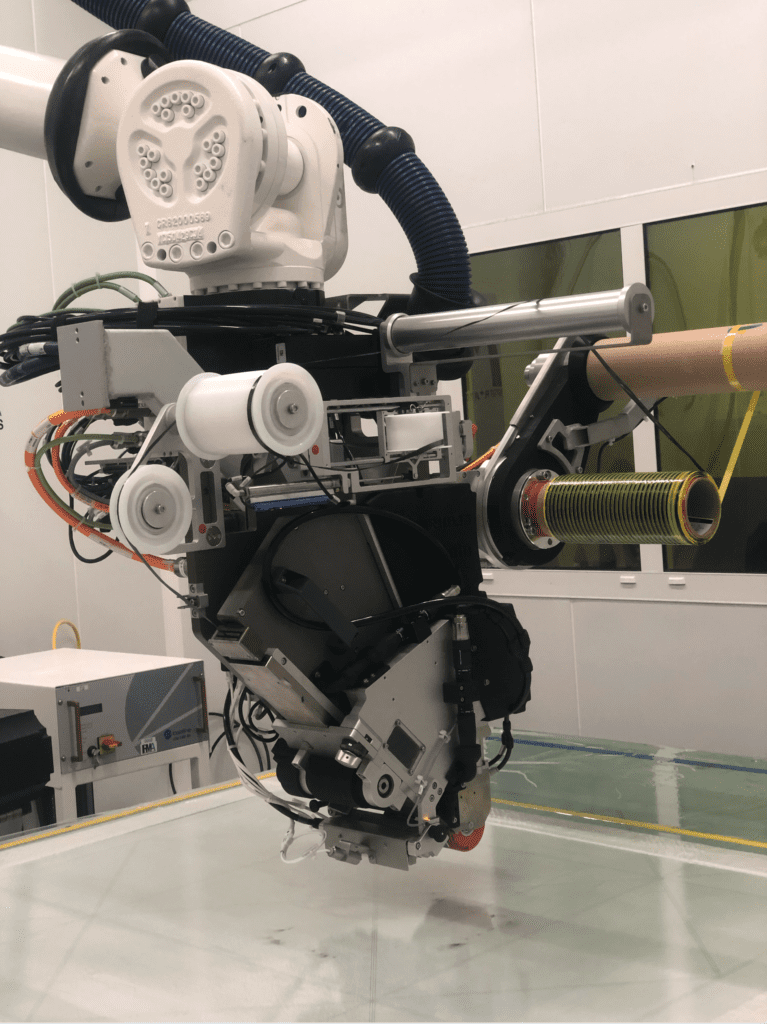

ComposiTIC is engaged in the development of Type IV Hydrogen tanks from the pre-study validation phase from specifications to the first tests (burst test, cycling).

Environmental impact

Thanks to its extensive R&D activity in the field of biomaterials and thermoplastic bio-composites, ComposiTIC is constantly on the lookout for emerging solutions for bio-sourced and/or biodegradable materials.

RECYCLING FOCUS

RECYCLING FOCUS

ComposiTIC has developed expertise in the recycling of high-performance polymers and composites.

- Different size reduction technologies: Retsch hammer mill with grid from 4 mm to 20 mm, shredder, 3DEVO mill

- Analysis of recycled materials and feasibility study of integration of these materials

- Prototyping of recycled formulations with custom characterizations

Digital design

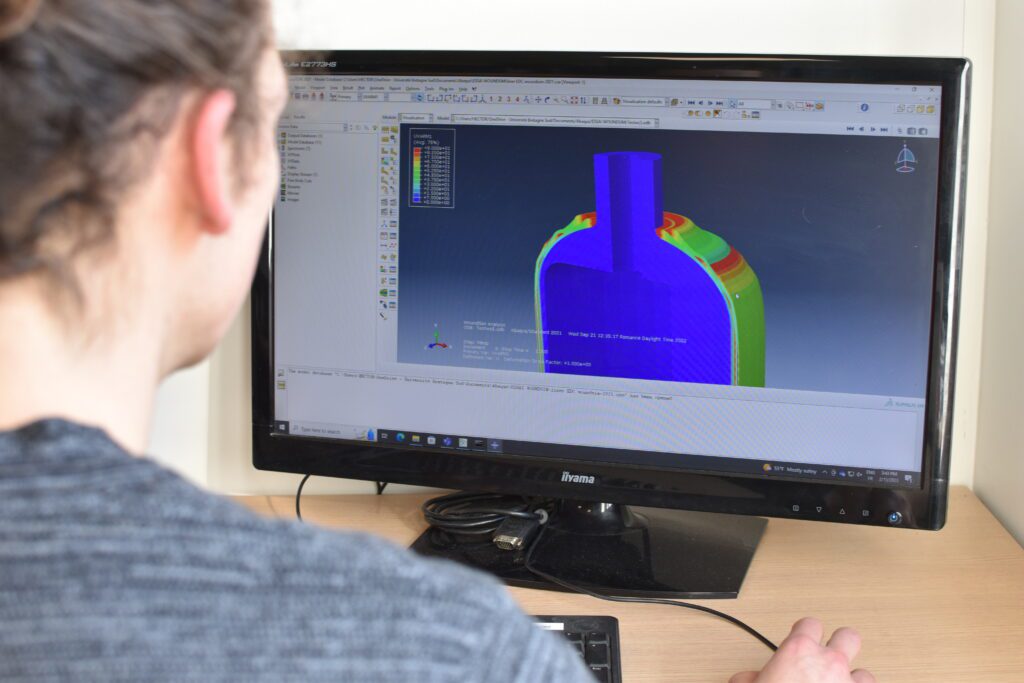

ComposiTIC has the means to characterise materials and digitally simulate them, from their implementation to their performance in use.

DIGITAL FOCUS

DIGITAL FOCUS

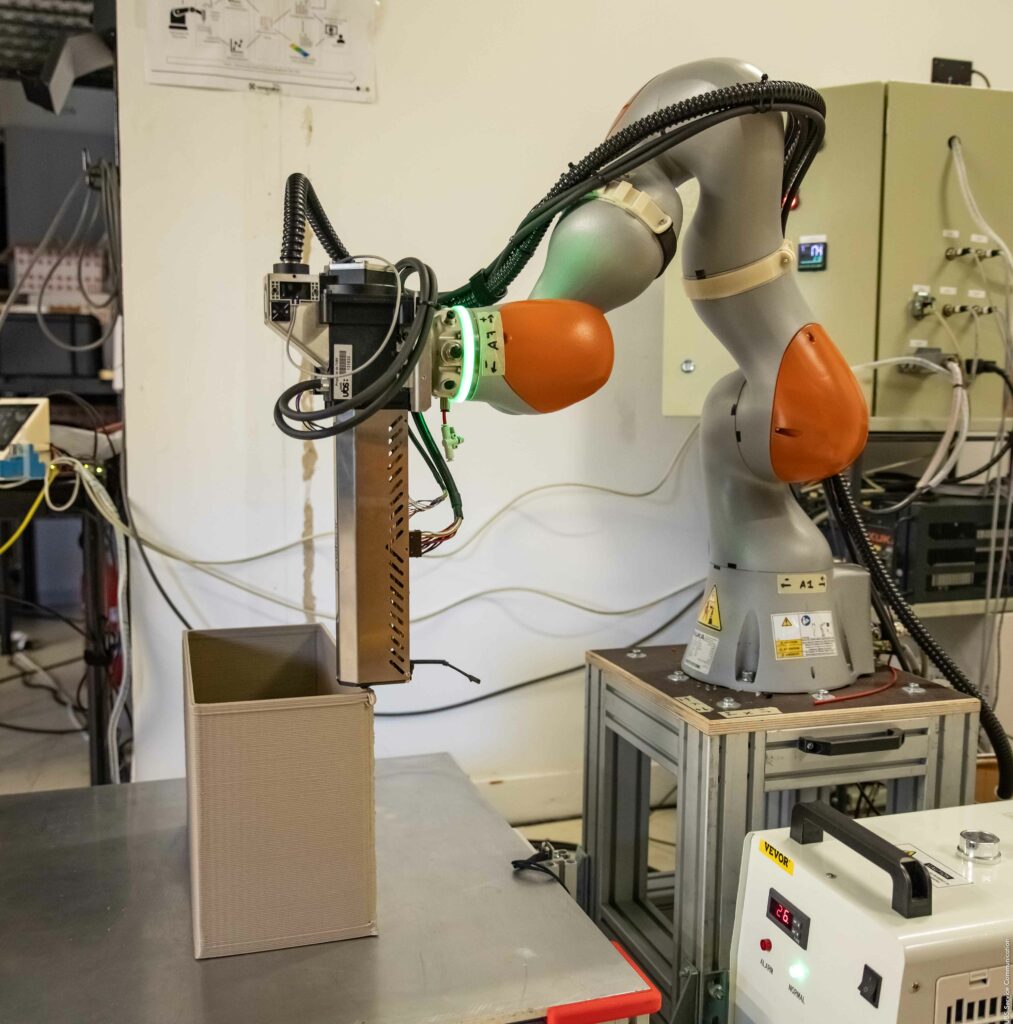

ComposiTIC carries out digital tests and predictions to obtain results as close as possible to the material used. The results of the digital simulations provide information on the physical flows (stress, thermal, rheological) in the material and the consequences for the structure (deformation, stress, etc.).

• Study of concepts and pre-sizing of structures using innovative materials.

• Validation of technical and economic assessments and business models.

• Prototyping Performance evaluation of plastics and composites processes.

• Multi-physics expertise to understand manufacturing phenomena.

Specific fields of application

• Digital twin to analyse and predict product and composite process behaviour – from sensors to Artificial Intelligence

• Design, prototyping and testing of Hydrogen tank

• Mechanical expertise and composite materials for Foil and boating

HYDROGEN FOCUS

HYDROGEN FOCUS

RECYCLING FOCUS

RECYCLING FOCUS

DIGITAL FOCUS

DIGITAL FOCUS